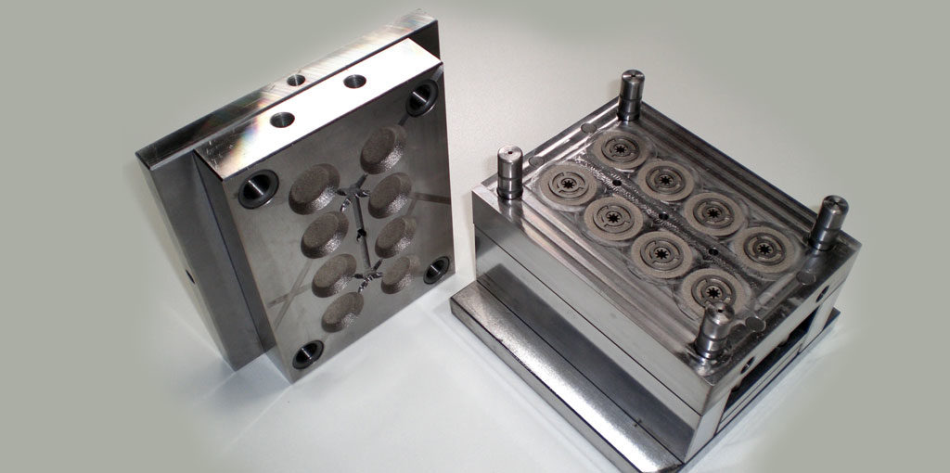

Our customers consider our tooling department to be the best source for manufacturing precision plastic injection moulds and dies. We operate 3 shifts to ensure that the moulds are built to meet ever-reducing lead times. Our quick turnaround time helps our customers get new projects off the ground within stipulated timelines. We use medium-hardened steel for pre-production moulds and hardened steel for high-volume mass production.

Our machining capabilities allow us to quickly turn part data into cores and cavities. Our CNC professionals can handle complex shapes and contours with ease. With high-speed 3-axis CNC mills, we can cut desired material quickly.

We use the latest mold development concepts to build molds with precision and longevity. We have full control of the entire mold making process with in-house CNC Milling, EDM/Wire EDM, and Polishing.

Our tool room is well adapted to the rigorous demands of tight tolerances and short lead-times of our customers, whether your need is for prototypes or high volume production moulds.